MMO Anode

Description:

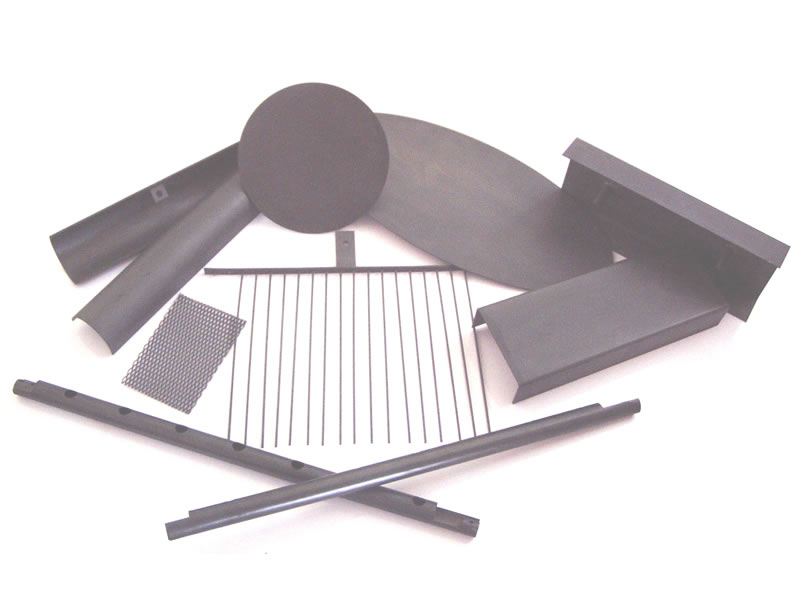

Mixed metal oxide anodes (MMO anodes) are anodes made by titanium coated with mixed metal oxide. It is a crystalline electrically-conductive coating that activates the titanium and enables it to function as an anode. MMO anodes have an extremely low consumption rate. They are widely used in soil, sea, mud, sewage and fresh water environments, etc. ZZ Industrial (Cathodic Protection) Shanghai Co.,Ltd provides high-performance mixed metal oxides (MMO anodes) for clients, which can be applied to electrosynthesis, chlorate and perchlorate production, electro-chlorination, electroplating, cathodic protection, sewage treatment of substrate, and so on.

Advantages of Mixed Metal Oxide Anode (MMO Anode):

1. This impressed current anode is of light weight.

2. MMO coatings have high chemical stability even in environments with very low PH values.

3. The coating of mixed metal oxide anodes is not affected by chlorine.

4. The wear rate of the MMO anode is extremely low and uniform. It is between 1 and 6 milligrams/ampere per year.

5. The anode dimensions remain nearly constant.

6. The mixed metal oxide can be operated at high current density, such as 2000A/m2.

7. It has superior electrically-conductive performance (10-7Ω·m).

Compositions of MMO Anode:

We provide two coating systems for different environments: Ir-Ta system, Ir-Ru system.

| Type | Coating Composition | Application |

| 1. | IrO2-RuO2-TiO2-X | Suitable for use in sea water where Cl2 is the principal anode product. |

| 2. | IrO2-TaO5-X | Suitable for use in soil, backfill, fresh water and sea water where O2, Cl2 or a combination of both are discharged at the anode. |

| 3. | Pt/Ti, Nb, Ta | Suitable for use in sea water |

Specifications of Mixed Metal Oxide Anode:

| Electrolyte | Maximum Design Current Density | Anode Life |

| Carbonaceous Backfill | 50 A/m2 | 20 years |

| Calcined Petroleum Coke | 100 A/m2 | 20 years |

| Fresh Water | 100 A/m2 | 20 years |

| Brackish Water | 100~300 A/m2 | 20 years |

| Sea Water | 600 A/m2 | 20 years |

| Anode for Cathodic Protection | ||||

| Ti Anode | Ti Standard | Type/Spec | Output Current | Life(Year) |

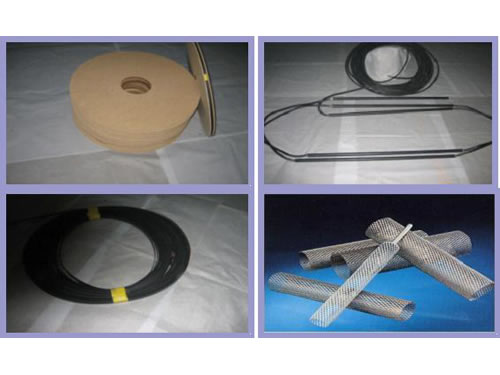

| Fiber(Silk) | Ф1.5 | 328 mA/m | 20 | |

| Ф3.0 | 656 mA/m | 20 | ||

| Ribbon | ASTM265 | 6.35×0.635 | 17 mA/m | 50 |

| 12.7×0.635 | 34 mA/m | 50 | ||

| Rod | Ф3.2 | 1.7 A/m | 20 | |

| Ф6.4 | 3.5 A/m | 20 | ||

| Ф12.7 | 6.9 A/m | 20 | ||

| Ф19 | 10.6 A/m | 20 | ||

| Ф25 | 13.9 A/m | 20 | ||

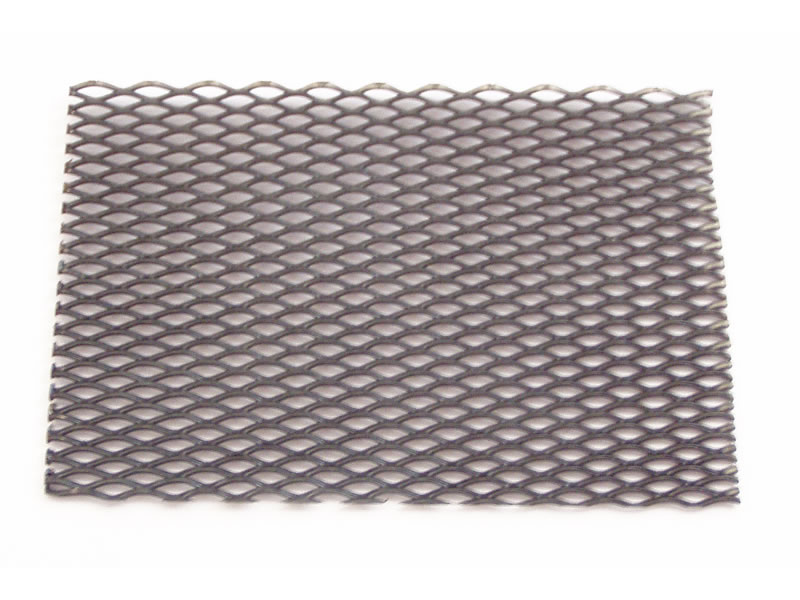

| Netting | ASTM265 | 32×1220×1 | 5A | 20 |

| 20×1000×1 | 2A | 20 | ||

| Tube | ASTM B338 | Ф19×1200×1 | 7A | 20 |

| Ф25×5000×1 | 4A | 20 | ||

| Ф25×1000×1 | 8A | 20 | ||

| Ф31×1200×2 | 12A | 20 | ||

ZZ Industrial (Cathodic Protection) Shanghai Co.,Ltd is a professional manufacturer and supplier of mixed metal oxide anode (MMO anode) in China. In addition to this impressed current anode, we are also engaged in producing silicon iron anode, graphite anode, flexible anode, etc. Based on 12 years' production experience, our products have been exported to the United States, Canada, Britain, Germany, Iran, Pakistan, India, Kuwait, Dubai, Saudi Arabia, the Philippines, Malaysia, Singapore, Congo, Turkey, etc.

- Graphite AnodeGraphite is a good conductor of electricity, which is low in cost and chemically resistant. Graphite anode is a conductive part of an electrical system or medium. It is commonly used in cathodic protection (CP) systems. This impressed current anode is also used to protect the structural integrity of buildings and metals, especially those that are underwater or underground. Within ...